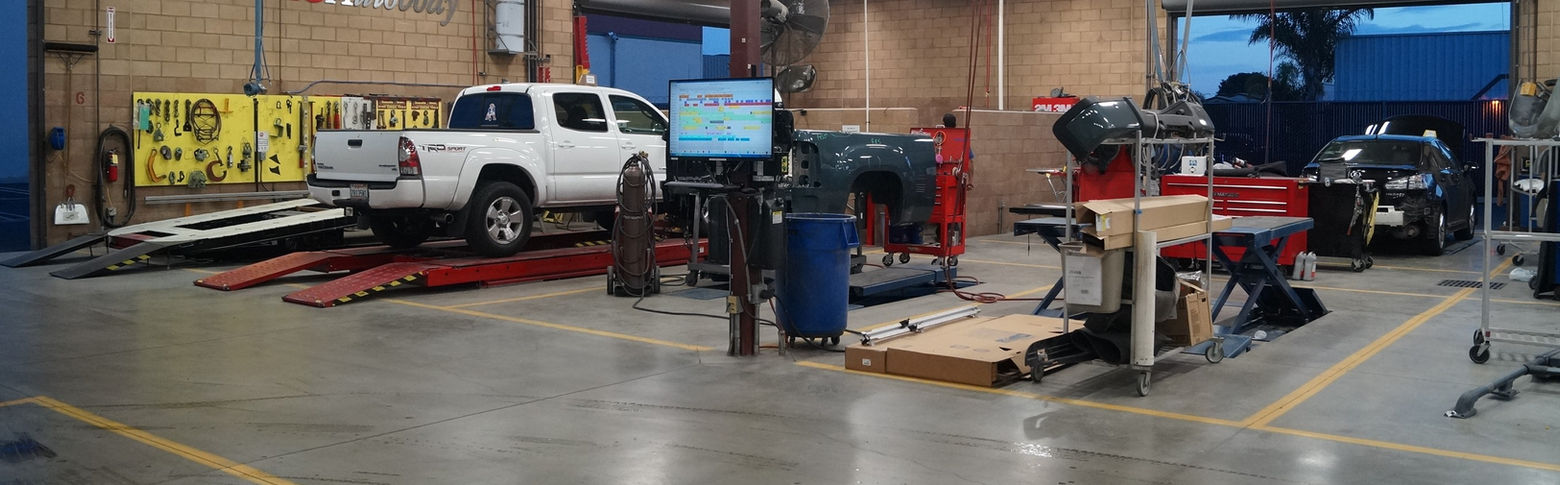

On & Off-Site Training & Consulting

It’s difficult to replace actually seeing and meeting staff and witnessing and

measuring the physical layout of each location. Conversations with key

staffing are a significant advantage over off-site planned communication.

Both on-site and off can be effective. On-site reduces the time required to

comprehend root causes & problems. Training classes can be delivered to

your staff on or off-site. See the listing of training classes available.

Tailored customer-specific training is also available.

Contact me for more information.

Business

Planning

-

Sales Strategy

-

Gross Profit Planning

-

Exception Management

-

Management-System Analysis-

-

Bonus Plans With Profit Containment

-

Team Hourly & Flat Rate Pay Plans (Our Specialty)

-

Job Descriptions

-

"NewHybrid" Repair-Plan Manager

-

Employee Handbook

-

Employee Reviews

Front

Office

-

DRP Management

-

Documentation &. File Management

-

CSI Communication: Verbal, Written, Web-Based

-

Estimating & Appraisal Process

-

Sales Technique, Conversion, Tracking

-

1100 Missed Operation

-

Estimating [Checklist]

-

Non Verbal Release Meetings

-

Job Costing

-

New Customer / Vehicle Check-in Process

(Implementing Repair Plan Managers)

-

Sustainable Repair Planning

-

Pre-Delivery

-

Close Process

-

KPI Performance Management

Parts Management

-

Parts Area Organization

-

Parts role in Sustainable Repair Planning

-

New Job descriptions

-

SOP Driven Performance

-

Vendor Selection

-

Parts Order Process Accountability

-

Web Part Sourcing

-

SOP Check-in Process

-

In-House Inventory System

-

PartTransportation

-

Supplemental Billing

-

Return for Credit

-

Communication, Scheduling,

-

Technician, Vendor

Production Management

-

Assigning Acountability

-

Triage Production Planning

-

Repair Planning

-

Visual Daily Production Planner

-

Hourly / Flat Rate

-

Incentive Compensation Plans

-

Lean Work Place Organization

-

Production Scheduling

-

Department Tracking

-

Efficiency Management

-

Shop-Wide Communication & Goal Setting

-

Lean Process Improvement

-

Eliminating Waste & Unapplied Labor

-

Verified Quality Step Inspections